Published:

Battery storage systems are fast becoming a cornerstone of the UK’s transition to a low-carbon energy future. As more intermittent renewable energy sources like solar and wind come online, the need to store excess energy for use during peak demand has never been greater. Battery Energy Storage Systems (BESS) are designed to do exactly that — capturing surplus energy and feeding it back into the grid when it’s needed most.

These systems don’t just increase energy efficiency — they also enhance grid stability, reduce reliance on fossil fuels, and support the electrification of transport. According to Solar Energy UK, battery storage is crucial to unlocking the full potential of solar power and enabling the UK to meet its net zero targets.

Investment and deployment in this sector are booming. As of early 2025, over 90GW of battery storage capacity is in the UK pipeline, with more than 4.5GW already operational. But as the number and scale of these installations grow, so too do the risks — both in terms of physical safety and security. Sites often sit in remote locations, making them vulnerable to theft, vandalism, and even arson. At the same time, concerns around fire safety — particularly lithium-ion battery fires — are prompting calls for national safety standards.

In this article, we explore why protecting battery storage installations is critical not just during operation, but from the moment ground is broken. From construction phase security to fire-resistant barriers and high-security fencing systems, we outline the best practices to ensure your BESS site is safe, insurable, and compliant.

The Rise of Battery Storage Installations in the UK

The UK’s battery storage sector has undergone explosive growth in recent years — and it’s not slowing down. Driven by decarbonisation targets, grid modernisation, and the rapid expansion of renewable generation, battery installations have become a vital component of national energy strategy.

According to the UK Parliament Library, the government aims to increase electricity storage to support a cleaner, more flexible grid, targeting up to 30GW of low-carbon flexible assets by 2030. This includes large-scale battery systems co-located with solar and wind farms, standalone utility-scale storage facilities, and even localised storage supporting EV charging infrastructure.

So, what exactly do these systems do? BESS installations help “smooth” the supply of power from intermittent renewables, storing excess energy when demand is low and releasing it when demand peaks. This balancing role is essential to prevent grid instability and avoid energy waste.

They also enable greater independence from fossil fuel peaking plants, lower energy bills for consumers through demand-shifting, and enhance resilience during outages. As the electrification of heating and transport accelerates, BESS is expected to play an even bigger role in supporting EV charging hubs, managing grid congestion, and integrating microgrids.

Battery storage installations can vary significantly in form and function:

- Containerised Units – the most common format, offering scalable and modular deployment.

- Underground or Enclosed BESS Systems – suited for urban or space-constrained sites.

- On-Grid vs. Off-Grid systems – some tied directly into the National Grid, others designed for independent operation.

But while their flexibility is a key strength, it also presents security and safety challenges. Different formats require different protection strategies — from fire-resistant barriers around high-density containers to secure fencing and surveillance at remote rural sites. As we’ll explore in the next sections, how you protect a BESS installation can be as critical as how you power it.

Crime Trends Around Rural and Renewable Energy Sites

As the UK’s battery storage and renewable infrastructure expands into more rural and remote locations, so too does a new and growing challenge: crime.

Energy infrastructure crime — once a niche concern — has become a real and rising threat to the successful deployment of battery storage and solar assets. Remote sites, often spread across large areas and lightly manned, are increasingly being targeted for their valuable materials and equipment.

The Rise of Rural Crime

According to recent data and industry reports, rural crime — particularly metal theft — is on the rise across the UK. Isolated energy sites have become prime targets for:

- Copper theft, especially from exposed cabling and earthing systems

- Break-ins, where criminals cut through inadequate perimeter fencing

- Vandalism, including damage to enclosures, containers, and control units

- Arson, often opportunistic and sometimes aimed at poorly protected temporary hoardings

Sites under construction are particularly vulnerable. Before commissioning, many BESS facilities store high-value electrical equipment, battery modules, inverters, and containers on-site, often before full security measures are installed. Without robust perimeter protection and site monitoring, this creates a high-risk window for theft and disruption.

Real-World Incidents

A 2023 analysis by DeterTech highlights a number of criminal incidents across UK solar and battery projects:

- Thieves stripping copper cabling from ground-mounted solar sites

- Repeated break-ins at sites where basic perimeter fencing had been breached or bypassed

- Delays to commissioning and insurance complications due to equipment theft during installation phases

These events are not isolated. Our own research has documented how many solar and energy developers previously saw perimeter fencing as an afterthought — only to suffer losses and downtime that could have been avoided with early-stage investment in site security.

Implications for Battery Storage Projects

For battery storage sites, the implications are serious:

- Equipment losses can delay grid connections by weeks or months

- Insurance premiums can rise sharply following incidents

- Safety risks increase where site integrity has been compromised

- Reputational damage can affect investor confidence in future energy projects

As deployment of utility-scale BESS installations increases, security is no longer a “nice to have” — it’s a critical enabler of project success. In the next sections, we’ll look at how security is currently specified on BESS sites, and where improvements can be made to better protect both the investment and the infrastructure.

Insurance Requirements and Compliance Considerations

As battery storage systems become larger and more complex, insurers are paying close attention to how these sites are secured and protected — not just from theft, but from fire, system failure, and environmental exposure. Securing a comprehensive insurance policy for a battery energy storage site now requires far more than a basic cover note.

Insurers are increasingly asking for clear, demonstrable evidence that risk mitigation strategies are in place — particularly for high-value BESS sites in remote or unstaffed locations. Failure to meet these expectations can result in:

- Higher premiums

- Reduced cover limits

- Or, in some cases, a refusal to insure the site altogether

Key Security Requirements From Insurers

According to guidance from PIB Insurance and forensic risk analysts Envista, insurers typically assess a BESS site against several key criteria:

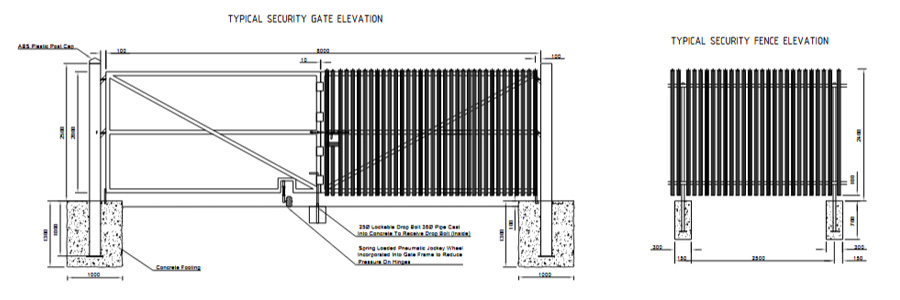

- Perimeter Security – High-security fencing, gates and access controls must be in place to prevent unauthorised entry, deter opportunistic theft, and slow down any forced access attempts.

- Surveillance and Monitoring – CCTV (preferably with offsite monitoring), motion detection, and alarm systems are now standard expectations — especially during unmanned hours or when the site is still under construction.

- Fire Risk Mitigation – Insurers are especially concerned about the potential for thermal runaway and battery fires. Sites that incorporate fire-resistant hoarding during construction and consider compartmentalisation, spacing between containers, and passive fire barriers are viewed more favourably.

- Intrusion Detection and Response Plans – Insurance providers want to see a response strategy in place — not just physical deterrents, but procedures for rapid action if an incident occurs.

How Poor Security Impacts Insurability

A BESS site that lacks robust fencing or fire protection is seen as a high-risk exposure. In many cases, incidents of theft or fire can render large parts of a system inoperable — leading to significant financial loss and project delays. From an insurance standpoint, the key risks include:

- Business interruption and lost revenue from energy generation

- Reputational damage to asset managers and developers

- Expensive claims related to battery fires, which can be extremely difficult to extinguish once ignited

Insurers may also require developers to demonstrate that any temporary security measures during the construction phase meet a defined standard, particularly when expensive electrical equipment is already on site.

Emerging Standards and Compliance Expectations

While the UK does not yet have a single national safety standard for BESS security, regulatory pressure is mounting. In the absence of formal regulation, many insurers and developers look to industry-recognised frameworks and third-party certifications, including:

- LPCB (Loss Prevention Certification Board) LPS 1175-rated fencing – tested and graded for resistance to forced entry

- Secured by Design – a police-endorsed initiative promoting crime prevention through effective design

- UKPN (UK Power Networks) and DNO guidance – specific to substations and grid-connected infrastructure, often used as a reference point for battery storage sites

- NFPA 855 and UL 9540A – while US-based, these are increasingly referenced in the UK when it comes to fire risk assessment and BESS layout planning

With regulators such as the Environment Agency and DESNZ actively reviewing the safety profile of large-scale battery storage, proactively addressing these requirements now can reduce risk, lower costs, and improve the long-term viability of a BESS project.

How BESS Security is Currently Specified

Despite the rapid deployment of Battery Energy Storage Systems (BESS) across the UK, security specification across these sites remains inconsistent — and in many cases, underdeveloped. While some developers integrate high-security measures from the outset, others treat perimeter protection as an afterthought, increasing their exposure to theft, vandalism, and insurance complications.

A key challenge lies in the lack of standardisation. With no single UK-wide code of practice governing BESS security design, specifiers must draw on a combination of industry guidance, insurer expectations, and lessons learned from related infrastructure sectors like solar and utilities.

Construction Phase Security Is Often Overlooked

Many BESS installations are targeted before they even become operational. During the construction and commissioning phase, valuable equipment such as battery containers, inverters, and switchgear is delivered and stored on site — often before permanent security is in place.

At this stage, temporary measures such as standard mesh fencing or timber hoarding are frequently used, but these offer little resistance to intrusion or fire. Without proper risk assessment, this creates a vulnerable window that criminals can exploit. Arson attacks or attempted cable theft can cause costly delays or even trigger insurance exclusions if adequate site protection isn’t demonstrated.

To mitigate these risks, best practice now calls for:

- Temporary fire-resistant hoarding with anti-climb features

- Early-stage surveillance (e.g. mobile CCTV towers)

- Controlled site access with monitored gate systems

Operational Security: What’s Being Specified

Once operational, BESS facilities require a permanent perimeter security strategy tailored to both physical and fire-related risks. While not yet mandated by regulation, several standards and frameworks are being adopted or referenced in specifications, including:

- LPS 1175-rated mesh fencing (e.g. SR1–SR2 grades) for proven resistance to forced entry

- BS 1722-14 compliant welded mesh perimeter systems

- Clear zones and exclusion areas around battery containers, as recommended in HSE and DESNZ fire safety guidance

- Integration with CCTV, intrusion detection, and monitored access gates

Security systems are increasingly being bundled with civil works, recognising that fencing, containment, and surveillance must work together to prevent unauthorised access and contain risks such as thermal runaway fires.

Real-World BESS Security Examples

Several recent projects illustrate how security is being applied in practice:

- Little Raith, Fife: IUS installed perimeter fencing, lighting, and fire detection systems as part of a 50MW Tesla Megapack deployment — showing that physical security is considered essential from the groundworks stage.

- Shilton Lane BESS, Erskine: Nairn Construction delivered the full fencing and gate package during civil works, ensuring the perimeter was secure long before commissioning.

- Utility-Scale BESS (undisclosed site):Safeguard Systems installed fencing alongside a smart CCTV and IR surveillance package to provide 24/7 intrusion detection.

Case Study: Solar + Battery Site, Winchester

While not a standalone BESS facility, a recent project completed that Alexandra helped supplier in Hampshire shares many of the same risks and requirements.

At a 35-acre renewable energy site combining solar generation and battery storage, we supplied and installed a full perimeter security fencing package. This included:

- Over 1,600 metres of high-security mesh fencing, specified to meet developer and DNO security requirements

- Secure double-leaf vehicle gates with anti-lift hinges

- Ground-clearance detailing to prevent intrusion from wildlife or trespassers

- Integration with future monitoring systems for off-site visibility

The installation demonstrates how early investment in robust perimeter security — designed with long-term operation in mind — can reduce risk and protect valuable energy infrastructure assets.

The Gap Between Theory and Practice

Too often, fencing and perimeter protection are treated as a late-stage procurement item — selected on cost rather than performance. This disconnect between perceived and actual security leads to:

- Inadequate fencing that fails insurance requirements

- Increased site crime during build phases

- Fire risk due to combustible hoarding or poor container spacing

- Delays in commissioning due to failed compliance inspections

As battery energy storage continues to expand in scale and criticality, security specification must catch up. That means involving perimeter protection experts earlier in the design phase and adopting a layered approach that considers construction, operation, and emergency scenarios.

Our Solutions for BESS Security

At Alexandra Security, we understand the unique security challenges posed by battery energy storage systems — from the vulnerable early stages of construction through to long-term operation. That’s why we offer a full range of fencing and gate solutions designed to protect BESS sites from intrusion, vandalism, and fire risk, while meeting insurer and client expectations.

Our perimeter systems have been specified on renewable energy sites across the UK, and are trusted by developers, contractors, and grid operators alike.

Early-Stage Protection Without the Compromise

Unlike many temporary setups that rely on timber hoarding or basic site fencing, we recommend installing the permanent perimeter system at the very start of construction. This approach provides immediate security for valuable on-site assets, avoids the fire risks associated with flammable hoarding, and eliminates the cost of temporary fencing that must later be replaced.

Where early installation isn’t possible, we can also provide rigid mesh fencing systems that offer far greater strength and security than traditional temporary panels, while maintaining site visibility and access control.

High-Security Fencing for Operational BESS Sites

Our permanent fencing systems are designed to withstand physical attack and environmental exposure, with features that meet or exceed the standards often requested by insurers, DNOs, and infrastructure consultants.

SolarGard Pulsar – A cost-effective yet highly secure solution for utility-scale energy sites. Anti-climb welded mesh panels with tamper-proof fixings and excellent visibility for CCTV integration.

SolarGard Pulsar Plus – An enhanced specification designed for high-risk or high-value installations, featuring tighter mesh apertures, increased height, and additional anti-tamper security features.

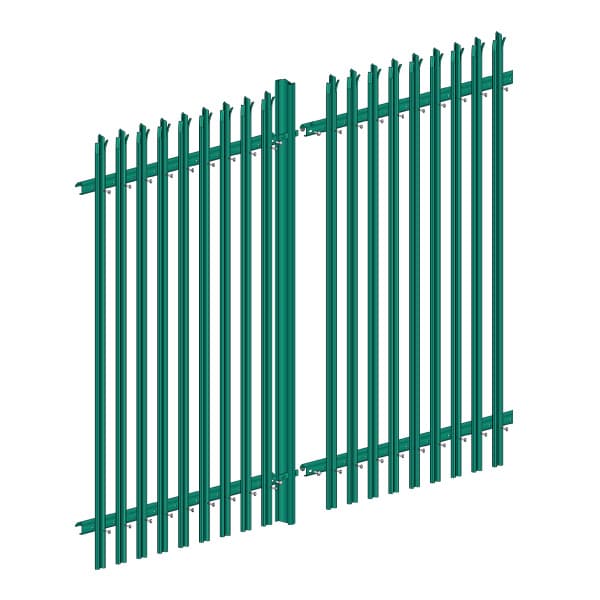

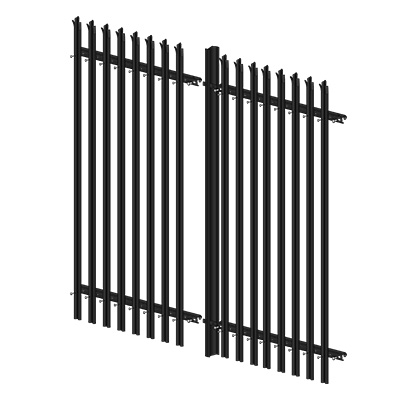

Protek Palisade – Ideal for sites requiring a more imposing visual deterrent or those already using palisade on adjacent infrastructure. Heavy-duty steel construction with sharp-pointed profiles and bolt-together fixings.

All systems can be paired with secure access control gates, vehicular entrances, and options for detection system integration or fire-zone compliance.

Turnkey Perimeter Security for Energy and Utility Projects

Whether you’re designing a new BESS site, upgrading an existing installation, or planning an integrated solar-and-storage facility, we can support you with:

- Expert advice on perimeter security design and layout

- Product specification guidance aligned to site risk, DNO requirements, and insurer expectations

- Supply and delivery of all fencing and access systems

- Case study-supported experience in the renewables and utilities sector

We’ve helped protect renewable energy projects across the UK, including a recent solar farm and battery storage site in Winchester. View the case study here.